At Renuka Auto Cast Tech Pvt. Ltd., our Low Pressure Die Casting (LPDC) facility embodies engineering precision and process excellence delivering aluminum components with exceptional strength, accuracy, and finish for diverse automotive and industrial applications.

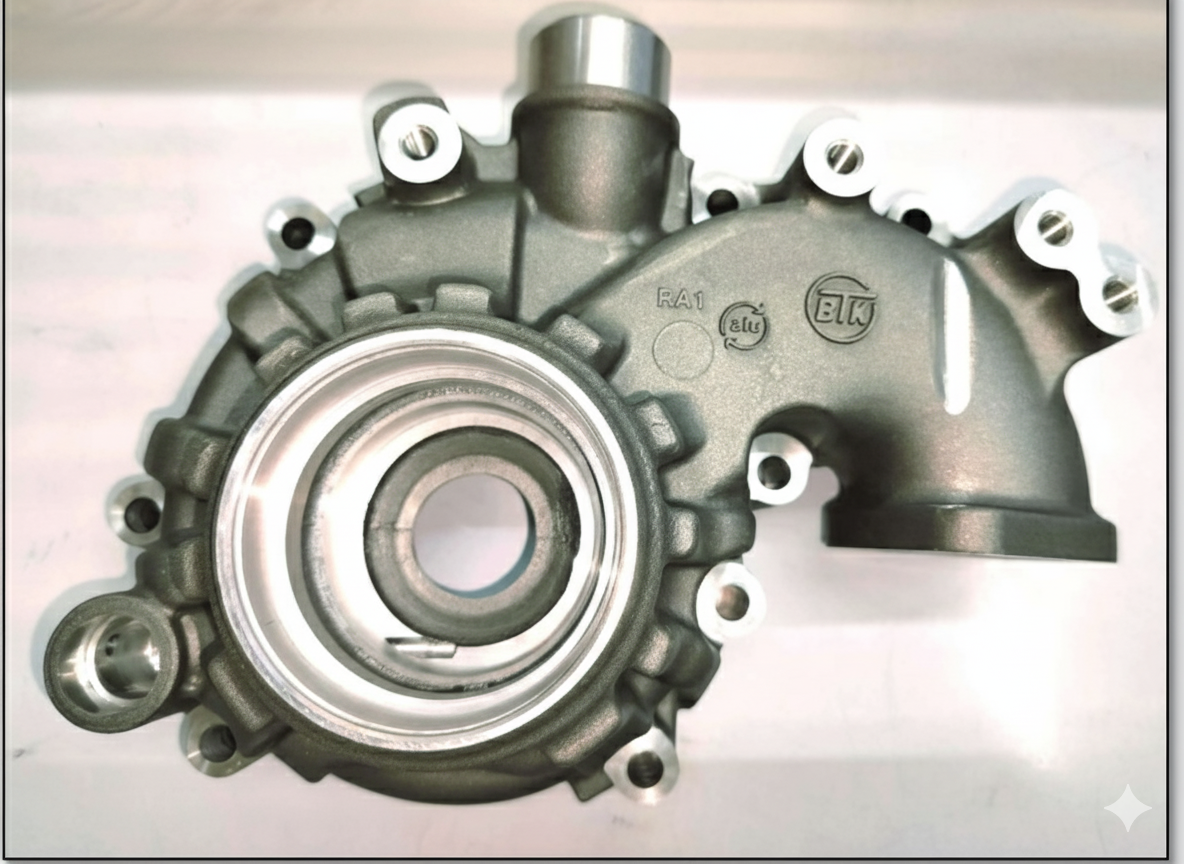

LPDC is a clean and controlled casting process where molten aluminum is gently pressurized into the die cavity. This ensures superior metallurgical integrity, minimal porosity, and a flawless surface finish ideal for structural and leak-proof parts such as water pump housings, motor housings, and battery enclosures.

Our LPDC setup is engineered to handle castings from 1 kg to 50 kg with bed sizes up to 1000 x 1000 mm, enabling us to produce both medium and large-size precision components with consistent quality.

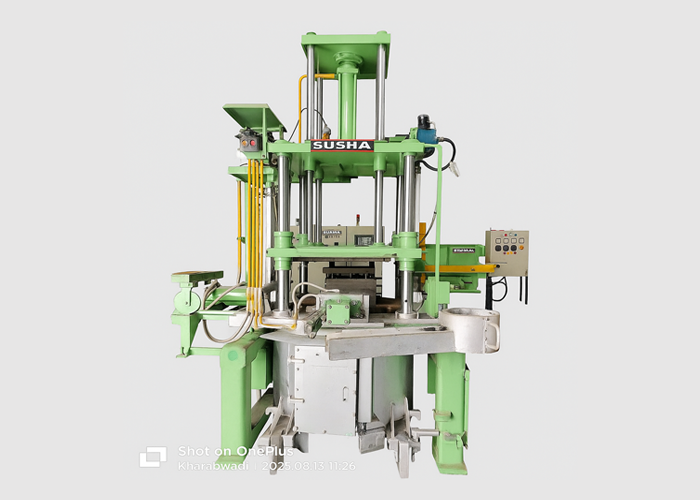

Key Features of Our LPDC Facility

- Advanced low-pressure casting machines ensuring dimensional accuracy

- Capability to produce lightweight yet robust aluminum parts

- Smooth casting surfaces suitable for machining, painting, or coating

- Excellent repeatability for high-volume production

- Integrated T6 heat treatment and post-casting operations

Process Flow

Casting → Fettling → Shot Blasting → T6 Heat Treatment → Machining → Washing → Leak Testing

Why Choose Renuka Auto Cast Tech Pvt. Ltd.

- Proven expertise in anti-gravity casting technology

- State-of-the-art infrastructure and process automation

- Zero-defect manufacturing through stringent quality controls

- In-house testing with X-Ray, Spectrometer, and Leak Test Stations

- Trusted supplier to leading OEMs in automotive, EV, and industrial sectors

At Renuka Auto Cast Tech Pvt. Ltd., we don’t just make castings we deliver performance, reliability, and precision in every component. Partner with us for next-generation LPDC solutions built to last.